Watarrka National Park ‑ Interpretive Seats - Kings Creek Walk

The project at Watarrka National Park involved the fabrication and installation of two interpretive seats along Kings Creek Walk.

This included preparing, pouring, and finishing concrete pads, assembling pre-fabricated seats with specific bolts, and installing Jarrah timber to the seats. Variations included additional costs for mobilisation, design works, fabrication, and installation, as well as adjustments for concrete footings and the removal of the requirement for a helicopter to sling in the seats. The project also accounted for increased labour, fuel, and material costs, and required detailed design and engineering adjustments.

Objective

The primary objective of the project at Watarrka National Park was to enhance the visitor experience along Kings Creek Walk by installing two interpretive seats. The goals and desired outcomes included:

Visitor Comfort and Engagement

Provide comfortable seating areas for visitors to rest and enjoy the natural beauty of the park, encouraging longer stays and deeper engagement with the environment

Interpretive Value and Aesthetic Integration

Design and install seats that blend with the natural surroundings, using materials like Jarrah timber to maintain the park’s rustic and

natural aesthetic.

Durability and Safety

Ensure the seats are durable and safe for public use, with robust construction and secure installation to withstand the elements and frequent use.

Sustainable Practices

Utilise construction practices to minimise environmental impact and align with the park’s conservation goals.

These objectives aimed to improve the overall visitor experience while preserving and highlighting the unique features of Watarrka National Park.

Challenges

The installation of the interpretive seats at Watarrka National Park faced several challenges:

Mobilisation

Additional costs and logistics were involved in mobilising the team and materials to the remote site. This included increased fuel and maintenance costs, as well as the need for additional vehicles to transport materials.

Design Adjustments

Significant time and effort were required for drafting and redrawing the seat designs,

which led to increased costs and extended project timelines.

Material and Fabrication Costs

Changes in the design and the need for specialised suppliers resulted in higher material and fabrication costs. This included additional freight costs and increased raw material prices.

Installation Logistics

The original plan to use a helicopter for lifting the seats was abandoned, requiring alternative methods for transporting and installing the seats. This involved using a Polaris Gator/trailer and a utility vehicle, which added complexity to the installation process.

Environmental Considerations

Ensuring minimal environmental impact during the installation process required careful planning and execution, particularly in a sensitive natural area like Watarrka National Park.

These challenges required adaptive solutions and meticulous planning to ensure the successful completion of the project.

Approach

Strategies and Methodologies:

Comprehensive Planning

BluedustNT began with detailed planning to ensure all aspects of the project were covered. This included site assessments, material sourcing, and logistical arrangements.

Collaborative Approach

Lowered the truss seating to a nominal height of 5000mm for better weather protection, following DIPL design advice.Engaged with stakeholders, including park management and local suppliers, to align on project goals and ensure community needs were met.

Adaptive Design

Incorporated feedback and made necessary adjustments to the design, ensuring the final product was both functional and aesthetically pleasing.

Steps Taken

Initial Assessment and Mobilisation

- Conducted site visits to understand the terrain and specific requirements for the installation.

- Arranged for accommodation and transportation of materials and personnel to the remote site, ensuring minimal disruption to the park environment.

Concrete Pad Preparation

- Prepared, poured, and finished concrete pads (1.6x0.7m, 200mm thick) to provide a stable foundation for the seats.

- Ensured high-quality workmanship to guarantee durability and safety.

Seat Assembly and Installation

- Assembled pre-fabricated seats using Mild M8 Bolts and Nuts, with specific attention to using black flathead bolts for the front seats to maintain a clean appearance.

- Installed Jarrah Timber with M10 Galv. Cup Head Bolts, ensuring bolts finished flush with the top of the timber for a smooth and safe finish.

Adaptation to Changes

- Managed additional costs and logistical changes, including increased labor, fuel, and material costs.

- Adapted to the removal of the helicopter requirement by using alternative transportation methods, such as a Polaris Gator/trailer and utility vehicle.

Design and Engineering Adjustments

- Dedicated 66 hours to drafting and redrawing the seats to accommodate changes in materials and supplier specifications.

- Ensured all design adjustments were thoroughly reviewed and approved by stakeholders before implementation.

Final Installation and Quality Check

- Completed the installation of the seats, ensuring they were securely fastened and met all safety standards.

- Conducted a final quality check to ensure the seats were installed correctly and met the client’s expectations.

By employing these strategies and methodologies, we successfully addressed the client’s needs, delivering a project that enhanced the visitor experience at Watarrka National Park while maintaining high standards of quality and safety.

Execution

The project at Watarrka National Park involved the fabrication and installation of two interpretive seats along Kings Creek Walk. Here’s a detailed description of the delivery, highlighting creative, logistical, and technical elements:

Creative Elements:

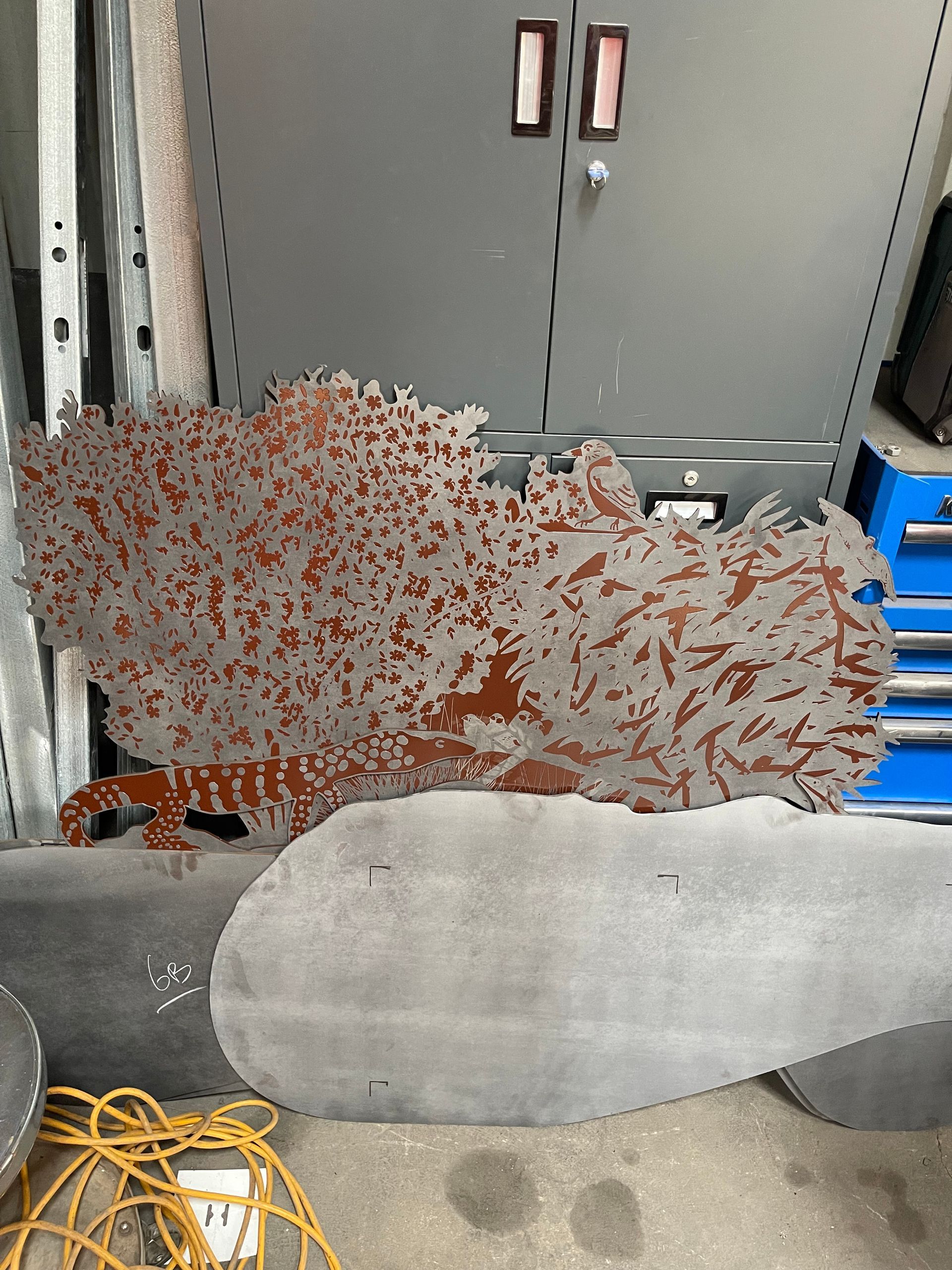

Design and Aesthetics

The seats were designed to blend seamlessly with the natural surroundings of Kings Creek Walk. The use of Jarrah timber provided a rustic and durable finish, while the black flathead bolts added a subtle, polished look to the front seats.

Interpretive Value

The seats were strategically placed to offer visitors a place to rest and enjoy the scenic views, enhancing the overall visitor experience with interpretive elements that connect them to the park’s natural and cultural heritage.

Logistical Elements:

Mobilisation

The project required careful planning for mobilisation, including accommodation at the Rangers Station and the transportation of materials and personnel to the remote site. The removal of the helicopter requirement necessitated additional vehicles and adjustments to the logistics plan.

Material Transport

Materials were sourced from various locations, including processed plates from Silverwater, NSW, and raw materials from Adelaide. This required coordination of freight and handling to ensure timely delivery to the sit

Site Access

Access to the installation sites was managed using a Polaris Gator/trailer and a utility vehicle, ensuring that all equipment and materials could be transported efficiently without the need for helicopter support.

Technical Elements:

Concrete Work

The preparation, pouring, and finishing of concrete pad (1.6x0.7m, 200mm thick) were critical to providing a stable foundation for the seats. This required precise measurements and quality control to ensure durability.

Seat Assembly

The pre-fabricated seats were assembled using Mild M8 Bolts and Nuts, with specific attention to using black flathead bolts for the front seats to maintain a clean appearance. The assembly process required technical expertise to ensure all components were

securely fastened.

Timber Installation

Jarrah timber was installed on the seats using M10 Galv. Cup Head Bolts, with bolts finished flush with the top of the timber. This required careful alignment and secure fastening to ensure the timber’s longevity and aesthetic appeal.

Design Adjustments

The project included significant design and engineering adjustments, with 66 hours dedicated to drafting and redrawing the seats. These adjustments were necessary to accommodate changes in materials, supplier specifications, and site conditions.

Overall, the project delivery was a success, combining creative design, meticulous logistical planning, and technical precision to enhance the visitor experience at Watarrka National Park.

Outcomes

MEASURABLE ACHIEVEMENTS

Concrete Pads

Successfully prepared, poured, and finished two concrete pads (1.6x0.7m, 200mm thick) for the seats.

Seat Assembly

Assembled and installed two pre-fabricated seats using Mild M8 Bolts and Nuts, with specific attention to using M8 Flathead Bolts in black finish for the front seats.

Timber Installation

Installed Jarrah Timber to the seats with M10 Galv. Cup Head Bolts, ensuring bolts finished flush with the top of the timber.

Adaptation to Changes

Managed additional costs and logistical changes, including increased labour,

fuel, and material costs, and

the removal of the requirement for a helicopter.

Design Adjustments

Completed additional design and engineering adjustments, including 66 hours of drafting and redrawing seats.

These achievements reflect the project’s successful execution and adaptability to various challenges.

More Projects